Cutting tools are essential to your repair and maintenance arsenal, whether you’re a professional or amateur. There’s a cutting tool for every project, but the range of tools available can be overwhelming. What kind of drill bit do you need, and which length is most appropriate? Which saw is best for cutting metal? When is a hole cutter a better option than a drill bit? Having a little knowledge of cutting tools is critical for choosing the best tool for the job.

Drill Bits

When it comes to cutting tools, drills are the most versatile and widely used. You have a vast selection of drill bits to choose from, which can be intimidating if you’re not sure what you need. To start, consider the material will be drilling. This will help you determine the best bit for your needs.

High Performance MRO (Maintenance Repair and Operations) Drill Bits

- Super Primalloy 135° Degree Split point drills are drill bits that have 135° point angles that are ideal in most maintenance applications. As the flatter 135° point can rotate quickly and take many smaller “bites” out of tougher metals. These split point drills are also self-centering and can eliminate the need for center punching before drilling- they won’t “walk or wander” all over the work surface when starting.

- Cryo-Gen SP are cryogenically treated split point drill bits. The controlled cryogenic treatment at temperatures down to -300°F, using liquid nitrogen, relieves metal stress in the drill bit and can greatly extend the tool life.

- Cryo-Gen N Drill Bits are cryogenically treated tools that have their margins (outer cutting edges) nitrated to make them harder and even more wear-resistant for even longer life than the standard cryo-gen drill bits.

- M42 Cobalt Drill Bits contain 8% cobalt content in the alloy. The addition of the cobalt makes the drill bit very resistant to heat that would otherwise cause a standard drill bit to lose it heat treat hardness and rapidly dull when drilling hard to drill materials. These are often ideal in very high-speed air-operated drill.

- Wood boring drill bits feature a small, pointy tip, which starts the hole. The spurs on the side scribe the hole, while the edges cut away the wood. These steel bits are ideal for softer woods and come in a variety of diameters.

- Sheet metal drill bits can also be used for wood, plastics and composites. They feature a brad point tip and cutting edges that provide clean holes. These bits are ideal for aluminum and mild steel and come in multiple diameters.

- Masonry drill bits do the tough work of drilling through tile, cement, brick and concrete and are ideal for use in plumbing and HVAC applications. They feature a carbide tip for long life and a wide spiral flute that removes dust from the cutting zone. Masonry bits come in multiple lengths and diameters.

- Glass and tile drill bits come in several diameters and are ideal for tile, ceramics, glass, mirrors, fiberglass and some laminates. The tip looks like a spear, which reduces cutting pressure and cuts cleaner holes. These bits also have a carbide tip and can be used in both hand-held drills and drill presses.

- A multi-task bit, like the Invader 2, may be an ideal choice for general purpose use, since it can drill through almost any material from metal to masonry to wood and be used in all types of rotary drills.

Popular MRO Drill bits come in three standarized lengths:

- Industrial/jobber is the longest standard-length bit, it provides additionally reach in hard-to-get-at areas.

- Maintenance/mechanics length is 15% shorter than the jobber length, making it more resistant to breakage.

- Screw machine/stubby is the shortest, making it more rigid and less prone to breakage. This is an ideal length for drilling sheet metal and other very thin metals.

- In addition to fractional and metric sized drills, we also carry number (wire) gauge and letter diameter drills. These drill bits provide size coverage in between the fractional sizes where high-tolerance holes need to be created and are often used to create the holes used for tapping operations.

Hole Cutters

Hole cutters are an ideal option for cutting larger holes because they work faster and use less power than drill bits. Instead of cutting the material from the center outward, hole cutters cut around the perimeter of where the hole will be formed, converting less material into cut chips and getting the job done much faster.

- K7 Hole Saws attach to your power drill. The teeth are designed to cut faster and last longer, cutting materials such as thin metals, pipe, nail-embedded wood, dry wall, plywood and plastics. Additionally, they provide maximum depth cutting and are fully capable of penetrating a 2x4. They range from ¾” to 5” in diameter.

- Roto-Kut Hole Cutters are designed to cut clean, precise holes 5 to 10 times faster than a drill bit and last 300 times longer than a hole saw. The cutting head cuts around the perimeter of the hole, converting a smaller amount of material into chips than a drill bit does, then ejects the slug. Roto-Kut can be used for cutting thicker metals, pipe, plastics and tubing, and ranges from 5/16” to 1-1/2” in diameter. Small diameter roto-kut cutters can cut metal up to ¼” thick while larger diameter cutters can go through up to ½” metal. When cutting through thick metal, a cutting tool lubricant, such as Ultra-Cut Gold Stick, is recommended.

- Roto-Kut Ultra Hole Cutters have carbide teeth that last even longer than the original roto-kut cutters and come in sizes up to 4 1/2” in diameter and can cut through steel up to 1” thick.

Burs

Burs attach to die grinders and are used to shape, grind and cut, as well as smooth sharp edges and remove excess material. You can use burs on a variety of materials, including metals. Burs come in various shapes and sizes with various tooth-geometries and specific coatings to allow them to perform different functions.

- Cylindrical flat end: used for contour finishing

- Cylindrical radius end: used for machining contour and to prepare metal edges for welding

- Cylindrical end cut: used for contour finishing and right-angled corners

- Counter-sink: used for beveling and acute angles

- Tree radius end: used for concave cuts and rounding off edges

- Tree pointed end: used for concave cuts, rounding off edges, and cutting into tight areas and angled contours

- Oval end: used for rounding edges

- Cone end: used for rounding edges and surface finishing in tight spaces

- Ball end: used for rounding edges, concave cuts and shaping/hollowing

- Ball nose cone end: used for rounding edges and surface finishing in tight spaces.

Multi Burs are designed to do the jobs of multiple burs and come in the following shapes: round end, radius end, pointed end and counter-sink.

Saw Blades

Chances are, you have at least one saw in your home or shop. They are versatile but not one-size-fits-all. Different saws perform different jobs.

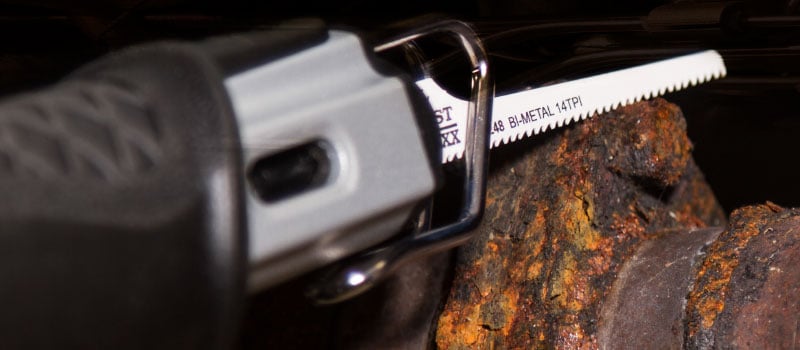

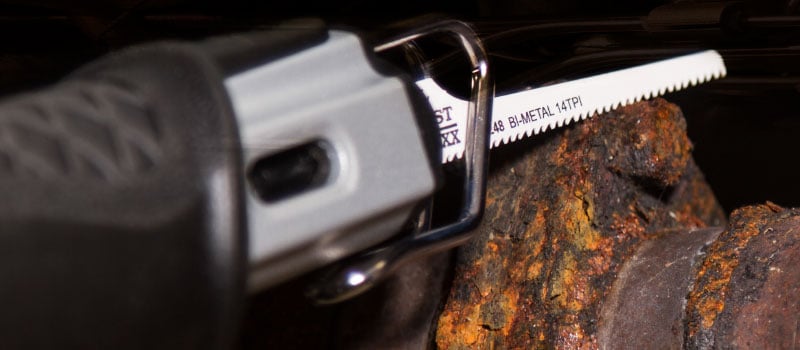

- A reciprocating saw is a workhorse that can get into tight spaces and is relatively easy to control. Reciprocating saw blades are used for tough applications, such as cutting through sheet metal, heavy gauge steel or nail-embedded wood.

- Cobalt-Maxx comes in 4”, 6”, 8”, 9” and 12” lengths with 10, 14, 18 or 24 teeth per inch.

- Cobalt-Maxx Air Saw comes in 3” or 4” with 14, 18, 24 or 32 teeth per inch.

- Demolition-Maxx comes in 6”, 9” and 12” lengths with 6, 10 or 14 teeth per inch.

- Cryo-Gen CM comes in a 6” length with 10, 14, 18 or 24 teeth per inch.

- Band saws are primarily used in a wide range of applications, from cutting wood to heavy gauge steel. Band saw blades can cut curves and irregular shapes.

- The jig saw’s versatility and ease of use makes it popular with DIYers and professionals alike. Jig saw blades are designed to cut wood, fiberglass, drywall and steel. You can use a jig saw for beveling and cutting curves. Our blades come in 2-7/8”, 3-5/8”, 4” and 5-1/4” lengths with 6, 10, 14, 18 or 24 teeth per inch and feature shatterproof, bimetal construction.

- Circular saw blades are ideal for many industries and applications. Some are designed for cutting hard and soft woods, paneling, plywood, chipboard or composites. Others, like the Metal Devil, are designed specifically for cutting metals. Our blades come in 7”, 7-1/4”, 8-1/4”, 9” and 10” diameters.

Taps and Dies

Taps and dies are used for cutting threads – taps create internal (female) threads and dies cut the external (male) threads. If a tap is used, it’s referred to as tapping. If a die is used, the process is called threading. Regardless, both are cutting threads.

Power-Taps drill and tap in one operation, eliminating the need to find the right size drill bit to get the correct hole tolerance for the tap. These taps also cut superior strength threads and can be used with materials up to twice as thick as the tap diameter. Conventional taps typically require a tap wrench in order to thread a pre-drilled hole.Whether you use a Power-Tap or conventional tap, you have other factors to consider, such as tap style (taper, plug or bottom), thread diameter, thread pitch, number of flutes, materials and finishes. When tapping, it’s advisable to use a lubricant, such as Hard-Kut, to maximize performance and extend tool life.

Dies are hexagonal or round and can be used with either die wrenches or standard adjustable wrenches. You can choose fractional, metric or pipe thread, but you also must consider thread diameter and thread pitch.

Reamers and Step Drills

Drilling large diameter holes in steel is difficult and time consuming if you’re using a hand drill. Reamers can be used in a hand drill (please use one with a side handle for safety) to enlarge a smaller pilot hole made with a drill bit. They cut cleanly and efficiently, deburring, enlarging and aligning holes. As with other cutting tools, a cutting tool lubricant is recommended for use with reamers.

Step drills have a conical shape with a series of cutting tool “steps” that make increasingly larger holes as you progress down the steps. Designed for metalwork, they can also be used for laminates, rigid plastics and other materials. The Ultra Bit Step Drill is useful when drilling into thin materials, like sheet metal, that might bend or buckle. One bit can produce up to 13 different hole sizes and can be used with a portable drill or drill press.

Unless you regularly work with cutting tools and know exactly what you need, it can be difficult to make sense of all the choices that are available. Luckily, our experts can guide you through our extensive line of cutting tools to help you choose what will work best for you.

.png?width=131&height=58&name=image%20(40).png)