So, you want to learn more about abrasives … Really, who doesn’t?

The first thing to know is … there are a lot of them. And using the right one for the job is crucial.

For example, even with a very careful, steady hand, a cutoff wheel is not going to give you the desired result for a refinishing project. You need to take the time to change your wheel, or even grinder, to the proper one for the job.

Clearly, the idea is to know what you want to do, even if it is a multi-step project, and get your tools laid out in front of you before you begin. Remember, as always, the lower the grit number, the more aggressive the wheel or disc. Kimball Midwest offers a variety of grits and sizes in many of the items below, so click the link to find out more on all of these.

Cut-Off Wheels/Grinding Wheels

As the name would suggest, cut-off wheels are made to cut things off. Be it a stubborn bolt, nail, separating a weld that is no longer needed or needs to be redone.

In short, cut-off wheels, grinding wheels and grinding discs are used to change the shape of metal. Either to cut it off, or to remove portions of it. They are not made for fine work. They leave the surface rough and it will likely need to be deburred and smoothed before using the pieces for their final application.

Kimball Midwest offers many different cut-off wheels for your various projects, including ceramic, Super Maxx, Super Maxx 2, Super Maxx Lightspeed, Endura Max and DiamondX.

Grinding wheels include many of the above names, as well as Kim-Kut Ultra grinding wheels.

Flap Discs/Flap Wheels

I mean they are weird looking, right? Kind of like a pinwheel on steroids.

They are built that way for a specific reason. (Side note, don’t try to use a pinwheel in the place of a flap disc. It … it won’t end well.)

But what are they used for? Flap discs are used to conform and shape metal. They have densely layered abrasive cloth flaps that can shape certain metals while leaving a finished look.

Most uses for flap discs and flap wheels are for welding, machining, agriculture, heavy duty equipment and food production. The wheels can be used for the interior of cylindrical objects as well.

Flap discs can give you the metal removal of grinding, and typically, the harder you push the more aggressive they are, while the application of light pressure gives you more of a finished look and feel. The discs and wheels tend to have more give and certainly have more flexibility than cut-off wheels and grinding wheels.

The more flaps on the disc or wheel (higher density) usually means it will last longer. A standard density can be more aggressive, but it is not as forgiving.

In the end, flap wheels and discs are a good combination of finishing, stock removal and shaping.

Flap discs and wheels come as: Dark Fire, Crimson Fire, Ultra Max, Kim-Flex, V.S.R., Blue Vue and Polifan. (Some of the items are not available for wheels).

Wire Wheels

Depending on what you are looking for, wire wheels fit in their own category. Wire wheels remove rust, paint, scale and corrosion. They can blend edges, clean forged components, and prep the surfaces of metal, rubber, plastic and other materials.

The difference between wire wheels and abrasives is that abrasives remove metal stock – but wire wheels do not, they simply clean and change surface finish.

Of course, there are several options. Each wheel does something a little different, so you’ll need to do a little of research based on what you are working on.

For example: Medium and narrow face wheels are for general use of deburring, edge blending and surface prep. While twisted knot wheels are for more high-impact action, removing rust, corrosion, weld scale and spatter.

There are also hand-held options in wire brushes.

Surface Conditioning Discs

Just about ready to start painting or re-assembling? These are options are for the final touch.

Surface prep discs are handy little tools that kind of look like steel wool or pot scrubbers.

They can remove just about anything on the surface of the metal with little risk of damaging it. Think of scrubbing burnt pudding from an aluminum pan. Not that anyone here has ever had to do that …

Surface prep discs are made from open non-woven nylon material, coated with abrasive grain. They remove corrosion, paint and other contaminants. Some of the products in the Kimball Midwest line are gentle enough to remove the paint from a soda can without damaging the can.

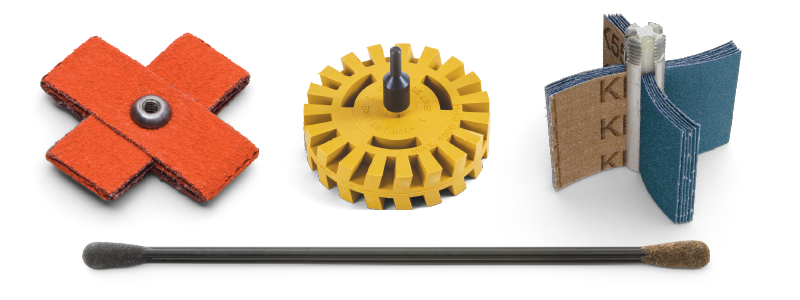

Some of the discs available from Kimball Midwest are: Kim-Brite KL, Kim-Brite Triple Tac, Cross Buffs, Buff and Blend Discs, Surface Maximizer Wheels, Scotch-Brite Roloc. There are hand-held options as well.

A Special Touch

Looking for something a little different? All that’s above is great, no doubt, but not giving you the tool you need?

We have more.

Bristle Discs: sweeps away gasket material without gouging the surface.

Kimball Midwest also stocks slotted and cross pads, bore polishers, Pro-Clean Sandit for precision cleaning and tight spaces, Surface prep pens and 3M stripe off wheels as well as Hub and brake rotor conditioners.

Want a more in-depth dive into what we offer and what they do? We are rolling out several more blog posts during our Abrasives Promotions, so keep looking at blog.kimballmidwest.com for additional information. Meanwhile, if you would prefer getting a local expert into your shop to demonstrate these abrasives,  .

.

.

..png?width=131&height=58&name=image%20(40).png)