Fasteners come in many shapes and sizes, but threaded fasteners are the most common. Many have specific uses, but hex head cap screws are a popular choice and work well in numerous applications. They are not created equally, though, so knowing the basics of cap screws and their component parts will help you choose the right one for your job.

Grade

Two of the most important considerations when selecting a hex head cap screw are the grade and material. You can find cap screws in standard (fractional) or metric.Industry-standard cap screws come in Grade 2, Grade 5 and Grade 8, as well as super-tensile strength like L9. All have different identifying markings. The higher the grade, the stronger the fastener. Metric cap screws come in 8.8, which is equivalent to a Grade 5, and 10.9, which is equivalent to a Grade 8.

For a deeper dive into grades and materials, read our last blog post, Upgrade Your Fastener Knowledge.

Anatomy

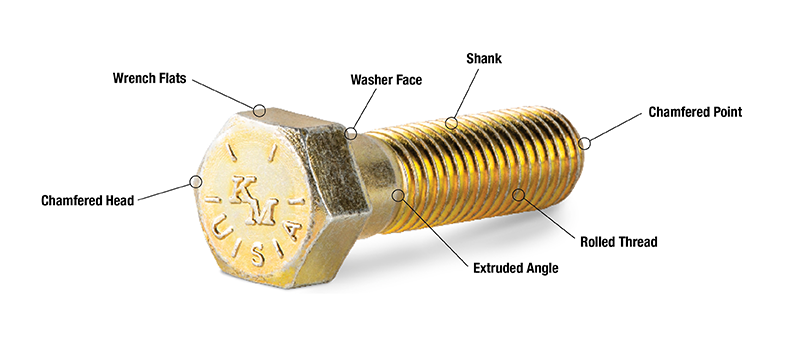

You may see certain terms such as “chamfered head” or “rolled thread” in the product description. Here’s a breakdown of basic hex head cap screw anatomy and what these terms mean:- Chamfered head: These are symmetrical sloped edges at the top of the screw head that allow for faster, easier access for wrenches and sockets.

- Wrench flats: These are flat sections on the head that form a strong surface area for wrenches and sockets to engage.

- Washer face: Located just beneath the head, this provides a smooth bearing surface for easier tightening, an even distribution of clamping force and prevents the sharp hex corners from digging into the surface of the work piece.

- Fillet (rounded corner): These contours under the washer face eliminate sharp edges and allow the load to be distributed evenly over the bearing surface of the head.

- Shank: The body of the fastener. This can be partially or fully threaded on longer cap screws; shorter cap screws may be fully threaded. Tap bolts are always fully threaded regardless of their length.

- Extruded angle: The area where the fastener shank is extruded to form the thread pitch diameter prior to thread rolling.

- Rolled thread: Smooth, well-formed threads produced by thread rolling dies. Screws can also have cut threads, which have less strength and durability.

- Chamfered point: Located at the tip of the shank, this aligns the threads of the mating nut for faster, easier assembly and reduces the possibility of cross-threading.

Thread Measurement

Cap screws come in a variety of lengths and diameters. It’s important to know how to properly measure them to ensure you have the correct size. A pocket caliper or other measuring tool is handy for this purpose, as well as a thread identifier.Length – This is the distance from the largest diameter of the head nearest to the thread to the end of the threaded portion.

Diameter – This is measured at the largest diameter beneath the head. When measuring across threads, always measure the maximum outside diameter of the thread.

You also need to determine whether coarse or fine threads are best for your needs.

Coarse (standard) threads are good for general applications, especially when using lower strength materials such as cast iron, mild steel, softer metals and plastics.

Fine threads are ideal for stronger materials and heavy-duty applications. In any given diameter, fine thread fasteners are stronger than coarse threads, as the finer threads are shallower and give a larger cross-sectional area.

You can determine the difference between coarse and fine threads by looking at the thread size. Guidelines are different for standard (fractional) and metric cap screws.

Standard thread sizes are identified by the diameter and number of threads per inch. Fine threads have a larger thread per inch (TPI) number.

Metric thread sizes are identified by the diameter and thread pitch. The thread pitch is the distance from one thread to the adjacent thread, with fine pitch having a smaller pitch distance.

Component Parts

Nuts – Be sure to use matching hex nuts, such as a Grade 8 hex nut with a Grade 8 cap screw. This is critical for the strength and safety of the fastener assembly. Like the cap screw, the strength of the nut relies on the diameter, thread series, construction material and hardness. However, the wall thickness and height also are important factors in the nut’s load-carrying capacity.Most nut heights, or thicknesses, are standard and will determine the length of the cap screw used. Ideally, no more than two or three of the cap screw threads should show beyond the end of the nut. Otherwise, there is a risk of thread stripping. There needs to be unengaged threads in the load-bearing area to support the clamp force.

Flat washers – Washers also are critical to the fastener assembly, since they increase the load-bearing surface beneath the cap screw head and nut and help distribute the load over a greater surface area on the assembled parts. The top of the washer is chamfered to mate with the underside of the fastener head.

Unlike the cap screws and nuts, washers do not have grades. But that doesn’t mean you can choose just any washer for your fastener assembly. The washer must be comparable in strength to the bolted assembly, otherwise it may indent, or dish, when force is applied. Use a high strength alloy flat washer with a Grade 5 or Grade 8 fastener. Alloy washers are typically designated as Grade 8 for simplicity, although the term technically only applies to the cap screws and nuts.

Washers come in USS and SAE patterns. USS washers have a larger outside diameter than SAE and distribute the load over a larger surface area. These are ideal for lower strength materials such as wood, rubber, aluminum and sheet metal. The inside diameter is typically larger than the SAE washers, meaning it does not allow full support under the head of the cap screw, although close-fitting washers are available with the same inside diameter as SAE washers. The USS pattern is typically not the first choice for Grade 8 and L9 fasteners.

SAE washers – have a smaller inside diameter to match the bolt size and are designed specifically for higher strength applications. They fully support the washer face under the head of the bolt to maximize load carrying ability. These washers are ideal for metal-to-metal applications and with Grades 5, 8 and L9 fasteners.

.png?width=131&height=58&name=image%20(40).png)