Effective chemicals are an important part of almost any MRO supply chain, but do you have the best option for your shop in all the top categories? Here are some important tips to keep in mind for each of five key chemical types that can be valuable in a wide variety of situations:

Penetrating Oils

There are many applications, especially in maintenance, where you need to remove mating parts – like a bolt and nut or fastener – that are frozen together by rust, surface contaminants, etc. If you can’t get them apart, you can’t make the repair.

That’s where a good penetrating oil comes in: to aid in disassembly – but first you need to get it where the problem is. You need something you can apply to the parts that can get into the thread form or wherever the problem is.

Powerful solvents in a high-performance penetrating oil can dissolve and penetrate baked-on grease and surface contaminants that otherwise get in the way of getting the penetrant where it needs to be to allow a successful separation. This reduces friction and provides amazing improvement in removing frozen and corroded fasteners.

Penetrating Greases

Penetrating greases get into areas where you can’t get a conventional grease. They spray out thin to get into tight spaces before setting up as a thick grease that will stay in place.

For example, let’s say you have a drive chain that needs lubrication in all areas. If you just spray a regular grease on the surface, it will just sit there on top and you won’t get good coverage inside the chain, which can lead to friction, heat, and premature wear.

The best lubricants provide superior penetration and coating. Unless you’re in a completely sealed system, liquids run out, so greases are used in areas where you can’t have a completely sealed system.

Solvents

Solvents also are on the must-have chemical list for many shops.

You’ll want a fast-drying, multi-purpose solvent for many applications, blasting away dirt, contaminants, and grime, leaving the surface clean and undamaged.

Many industrial facilities require a non-chlorinated solvent, many of which are safe on most plastic and rubber parts, but usually are highly flammable, so you just need to make sure it fully evaporates after use before bringing a heat source or electricity around.

Chlorinated solvents generally aren’t flammable, but they do have hazards of their own to watch out for like harmful vapors and potential damage to plastic and rubber surfaces. Non-chlorinated solvents also often have hazardous vapors, so always read the warnings on the product label.

A different group of solvents also are available for use on electrical contacts or non-energized circuitry.

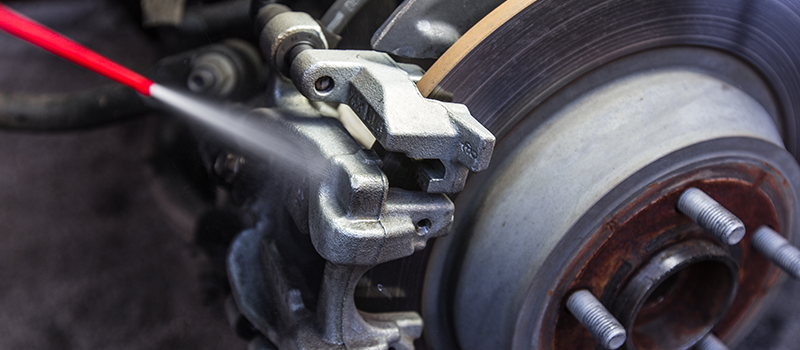

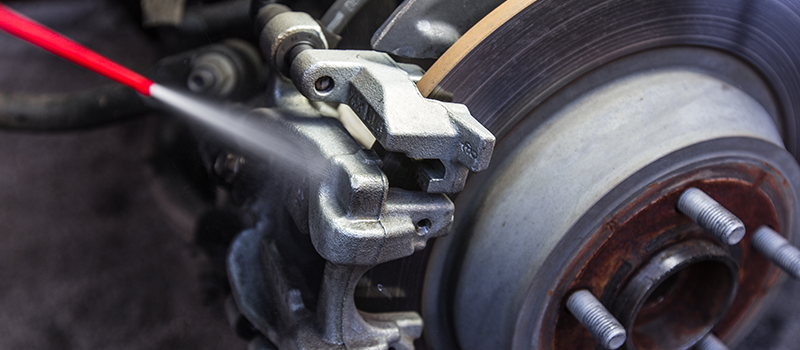

Brake Cleaners

Obviously, brake cleaners are designed to flush away brake fluid, grease, and more from the area of brakes, but they usually can do so much more. Even shops not dealing with brakes often find use for a quality brake cleaner as an effective all-purpose degreaser to clean other metal parts.

It’s OK to do this with most formulas because it doesn’t go against the labeling, but be sure to check your product’s label to ensure your planned use is appropriate.

Non-chlorinated brake cleaners tend to dominate the market today, but some applications need more aggressive degreasing and/or non-flammability, so chlorinated brake cleaners still are available.

One thing to be aware of is that chlorinated brake cleaners must be disposed of as hazardous waste. Small quantities can contaminate waste oil or other fluids and lead to significantly higher disposal costs.

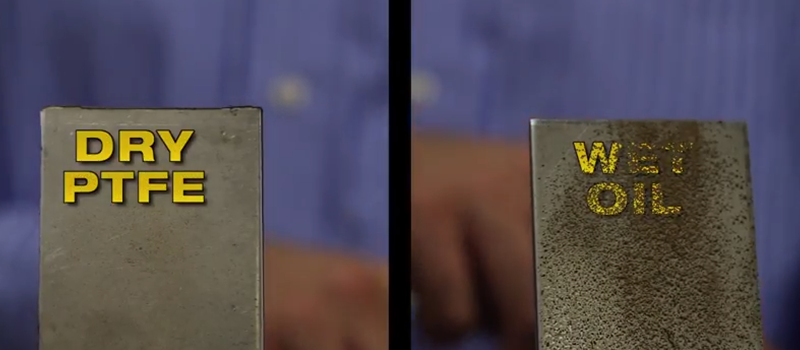

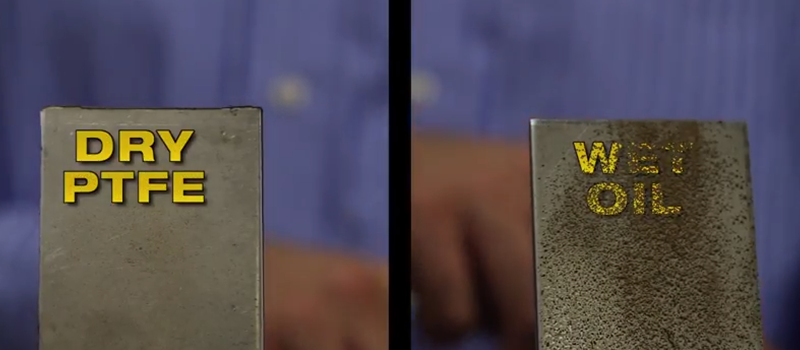

Dry Lubricants

Dirt and dust can stick in grease and other conventional lubricants, leading to abrasion and potential damage to the parts they are meant to protect. That’s where dry lubricants, which can be made of a variety of materials, come into play.

Dry lubricants are a popular category, and many can handle extreme situations, with some effective at more than 1,000 degrees Fahrenheit and loads of up to 100,000 PSI.

.png?width=131&height=58&name=image%20(40).png)