So you’ve picked out the right cutting tool for the job? That’s great, but before you get started, don’t neglect a few key categories of things you’ll need to get the job done right: cutting tool fluids, safety equipment and deburring tools.

Cutting Tool Fluids

Cutting metal generates a lot of friction and thus, heat. That’s why cutting tool fluids are used to lubricate and cool during processes including drilling, tapping, reaming, threading, milling, stamping and machining. These fluids are designed to keep temperatures in a consistent range, preventing damage to the workpiece and the tool.- Cutting tool coolant absorbs heat to lower the operating temperature and extend tool life. It also reduces friction for a cleaner, more precise cut for added efficiency. You’ll want to make sure your coolant is clear so you can always see the workpiece.

- Cutting tool compound provides similar properties and benefits as coolant while also clinging to vertical and curved surfaces for full work contact.

- Cutting tool gel resists throw-off and doesn’t splatter like some thinner fluids, meaning less mess and more efficient use, especially in high-performance applications.

- Cutting tool paste lubricants are designed to be applied directly to the cutting tool and stay where they’re applied.

Safety Equipment

Several kinds of safety equipment are available when using cutting tools to protect workers against debris, sparks, cuts and more:Deburring Tools

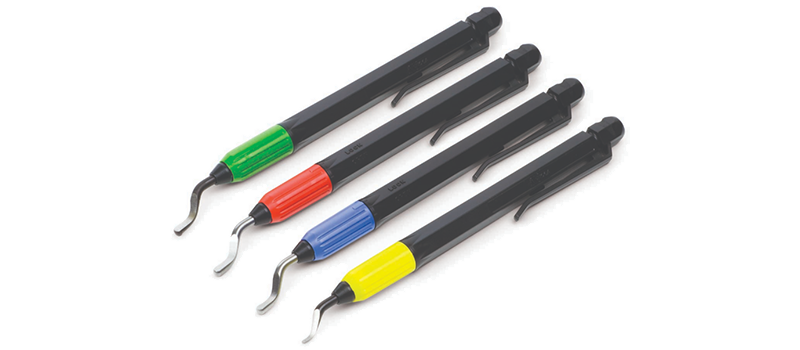

The third and final accessory category to keep in mind is deburring tools, which remove burs created when cutting materials including aluminum, mild steel, copper, brass, cast iron, steel, stainless steel and plastic. Different blades are appropriate depending on what sort of material is being cut.Deburring is important to eliminate dangerous sharp edges and make the finished surface smooth, even and safe.

.png?width=131&height=58&name=image%20(40).png)